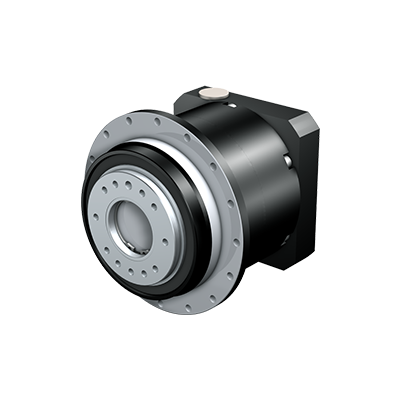

PHV Series

Precision for typical servo applications. For ratios > 60. Helical gearing. Highest torsional and tilting stiffness. Backlash up to < 3 arcmin. Flange output shaft. Short motor adapter length. Easy and secure motor mounting. Can be attached to almost any make of servo motor.

- 产品简介

- 产品特点

- 产品规格

- 产品尺寸

- 资料下载

Shaft Designs

Flange shaft

Bearing Design

Pretensioned angular contact bearings at the output in an O-arrangement, ideally suited for helical geared rack and pinion drive.

Mounting Positions

- Any mounting position.

Lubricants and Maintenance

- Synthetic lubricant CLP HC ISO VG 150

- Lubricated for life

- Maintenance-free

Paint Finish

Black RAL 9005

Motor Adapter ME

- Universal motor mounting system for almost all synchronous servo motors.

- Option large (MEL) for large motors.

- Fast and secure motor mounting.

- Robust, balanced coupling.

- Thermal length compensation.

- Low mass inertia.

EasyAdapt

Option ServoStop

- Integrated in the motor adapter, electrically released spring-loaded brake.

- When the power is removed, in the event of a power failure or an emergency stop ServoStop will brake both drive and machine shaft safely and reliably.

- Zero-backlash plug-in coupling.

ServoStop Motor Adapter with Brake

Option ServoCool

- Ventilation system for motor adapters ME and MF.

- With integrated radial fan.

- Allows operation at higher speeds or higher surrounding temperatures or helps reduce the temperature on the axis.

- Universal motor mounting system for almost all synchronous servo motors.

- Option "large" for large motors.

- Fast and secure motor mounting.

- Integrated clamp coupling for motor shafts without key.

- Robust, balanced coupling.

- Thermal length compensation.

Motor Adapter with Radial Ventilator

Recommendation Motor

EZ synchronous servo motors

For further information see Synchronous Servo Motors

Flange shaft

Bearing Design

Pretensioned angular contact bearings at the output in an O-arrangement, ideally suited for helical geared rack and pinion drive.

Mounting Positions

- Any mounting position.

Lubricants and Maintenance

- Synthetic lubricant CLP HC ISO VG 150

- Lubricated for life

- Maintenance-free

Paint Finish

Black RAL 9005

Motor Adapter ME

- Universal motor mounting system for almost all synchronous servo motors.

- Option large (MEL) for large motors.

- Fast and secure motor mounting.

- Robust, balanced coupling.

- Thermal length compensation.

- Low mass inertia.

EasyAdapt

Option ServoStop

- Integrated in the motor adapter, electrically released spring-loaded brake.

- When the power is removed, in the event of a power failure or an emergency stop ServoStop will brake both drive and machine shaft safely and reliably.

- Zero-backlash plug-in coupling.

ServoStop Motor Adapter with Brake

Option ServoCool

- Ventilation system for motor adapters ME and MF.

- With integrated radial fan.

- Allows operation at higher speeds or higher surrounding temperatures or helps reduce the temperature on the axis.

- Universal motor mounting system for almost all synchronous servo motors.

- Option "large" for large motors.

- Fast and secure motor mounting.

- Integrated clamp coupling for motor shafts without key.

- Robust, balanced coupling.

- Thermal length compensation.

Motor Adapter with Radial Ventilator

Recommendation Motor

EZ synchronous servo motors

For further information see Synchronous Servo Motors

|

Type |

Ratio |

Max. perm. acceleration torque [Nm] |

Max. perm. input speed in cyclic operation [1/min] |

Backlash [arcmin] |

Torsional stiffness [Nm/arcmin] |

|

PHV933 |

61 – 121 |

4250 |

4500 |

3 |

804 – 848 |

|

PHV1033 |

61 – 91 |

7500 |

4500 |

3 |

1339 – 1368 |