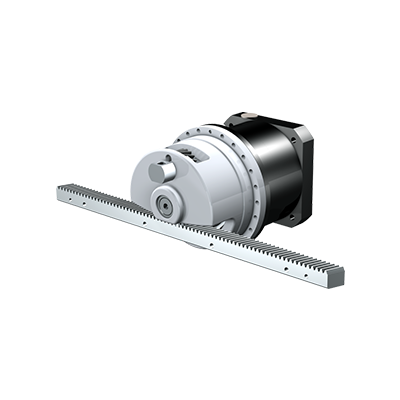

ZTRSPHQ Series

Quattro power due to four-planet system. Screwed down supporting bearing cover. Integrated pinion. Optional with felt gear. Helical gearing. On request: reduced backlash, angular input, direct motor mounting.

- 产品简介

- 产品特点

- 产品规格

- 产品尺寸

- 资料下载

Supporting Bearing Cover

- Robust cast housing

- Optimized for stiffness due to internal ribs.

- The supporting bearing permits maximum feed force, minimizes the bending and increases the service life.

- Closed protected construction.

Output pinion

- Gearing quality 5

- Case hardened and ground

- Optional concentricity ≤ 10 µ

The choice of a pinion, which is as small as possible, reduces torque allowing the use of a smaller gear unit.

ZTRS Output Pinion

ATLANTA Gear Racks

Our cooperation partner Atlanta offers matching gear racks for our products.

http://atlantagmbh.com/products/racks/

Mounting Positions

- Any mounting position.

- You can find the explanation of the mounting positions and the respective quantities of lubricant in the document Quantity of lubricant for gear units ID 441871

Lubricants and Maintenance

Gear unit:

- Synthetic lubricant CLP HC ISO VG 150

- Lubricated for life

- Maintenance-free

Rack and pinion drive:

- Optionally lubrication with felt gear

- Connectiion available for central lubrication or lubricator

- Lubrication of the rack and pinion drive must be carried out by the customer.

- For this purpose, we recommend only the use of high quality synthetic oil based grease of NLGI grade 0.

Felt Lubrication Pinion (Option)

Paint Finish

Black RAL 9005

Motor Adapter ME

- Universal motor mounting system for almost all synchronous servo motors.

- Option large (MEL) for large motors.

- Fast and secure motor mounting.

- Robust, balanced coupling.

- Thermal length compensation.

- Low mass inertia.

EasyAdapt

Option ServoStop

- Integrated in the motor adapter, electrically released spring-loaded brake.

- When the power is removed, in the event of a power failure or an emergency stop ServoStop will brake both drive and machine shaft safely and reliably.

- Zero-backlash plug-in coupling.

ServoStop Motor Adapter with Brake

Recommendation Motor

EZ synchronous servo motors

For further information see Synchronous Servo Motors

- Robust cast housing

- Optimized for stiffness due to internal ribs.

- The supporting bearing permits maximum feed force, minimizes the bending and increases the service life.

- Closed protected construction.

Output pinion

- Gearing quality 5

- Case hardened and ground

- Optional concentricity ≤ 10 µ

The choice of a pinion, which is as small as possible, reduces torque allowing the use of a smaller gear unit.

ZTRS Output Pinion

ATLANTA Gear Racks

Our cooperation partner Atlanta offers matching gear racks for our products.

http://atlantagmbh.com/products/racks/

Mounting Positions

- Any mounting position.

- You can find the explanation of the mounting positions and the respective quantities of lubricant in the document Quantity of lubricant for gear units ID 441871

Lubricants and Maintenance

Gear unit:

- Synthetic lubricant CLP HC ISO VG 150

- Lubricated for life

- Maintenance-free

Rack and pinion drive:

- Optionally lubrication with felt gear

- Connectiion available for central lubrication or lubricator

- Lubrication of the rack and pinion drive must be carried out by the customer.

- For this purpose, we recommend only the use of high quality synthetic oil based grease of NLGI grade 0.

Felt Lubrication Pinion (Option)

Paint Finish

Black RAL 9005

Motor Adapter ME

- Universal motor mounting system for almost all synchronous servo motors.

- Option large (MEL) for large motors.

- Fast and secure motor mounting.

- Robust, balanced coupling.

- Thermal length compensation.

- Low mass inertia.

EasyAdapt

Option ServoStop

- Integrated in the motor adapter, electrically released spring-loaded brake.

- When the power is removed, in the event of a power failure or an emergency stop ServoStop will brake both drive and machine shaft safely and reliably.

- Zero-backlash plug-in coupling.

ServoStop Motor Adapter with Brake

Recommendation Motor

EZ synchronous servo motors

For further information see Synchronous Servo Motors

|

Type |

Module [mm] |

Teeth number |

Max. perm. acceleration feed force [kN] |

Max. feed velocity [m/s] |

Linear backlash [μm] |

|

ZTRS10_PHQ1032 |

10 |

15 |

126 |

0.56 – 1 |

69 |

|

ZTRS8_PHQ1032 |

8 |

19 |

124 |

0.56 – 1.1 |

70 |

|

ZTRS10_PHQ1033 |

10 |

15 |

126 |

0.06 – 0.3 |

69 |

|

ZTRS8_PHQ1033 |

8 |

19 |

124 |

0.06 – 0.31 |

70 |